Cleaning Up Graphene Key to Commercialization

Over the years, graphene has earned many adjectives. Some have called it the ‘mind-boggling wonder material,” while others have termed it a ‘proven supermaterial.’ The world woke up to the wonders of graphene more than a decade ago.

İçindekiler

In 2012, Nature published an article titled ‘A roadmap for graphene,’ which elaborated on why Graphene was fast emerging as the apple of the eye of the scientific community. Researchers highlighted Graphene’s properties as a reason behind this interest, saying:

“This one-atom-thick fabric of carbon uniquely combines extreme mechanical strength, exceptionally high electronic and thermal conductivities, impermeability to gasses, as well as many other supreme properties, all of which make it highly attractive for numerous applications.”

Realizing graphene’s potential, the European Union decided to devote 1 billion Euros or US$1.3 billion to it between 2013 and 2023. The investment aimed to ascertain graphene’s transformative capabilities, especially when applied to electronics, energy, health, construction, etc. These initiatives received the backing of a long research trail, as over 8,000 papers were written about graphene between 2005 and 2013.

Since then, interest in Graphene among the scientific community has not waned. Now, researchers are looking into ways to commercialize Graphene further on a larger scale. In one such study, a team of engineers at Columbia University, along with colleagues at the University of Montreal and the National Institute of Standards and Technology, looked into the possibilities of cleaning up Graphene, making it ready for large-scale, commercial reproduction.

Addressing the Challenges Faced by Chemical Vapor Deposition (CVD) Synthesis of Graphene

CVD has been one of the two traditional methods of synthesizing graphene, with the other one being the ‘scotch-tape’ method. The method, also known as CVD growth, achieves its goals by passing a carbon-containing gas, such as methane, over a copper surface at around 1000 °C.

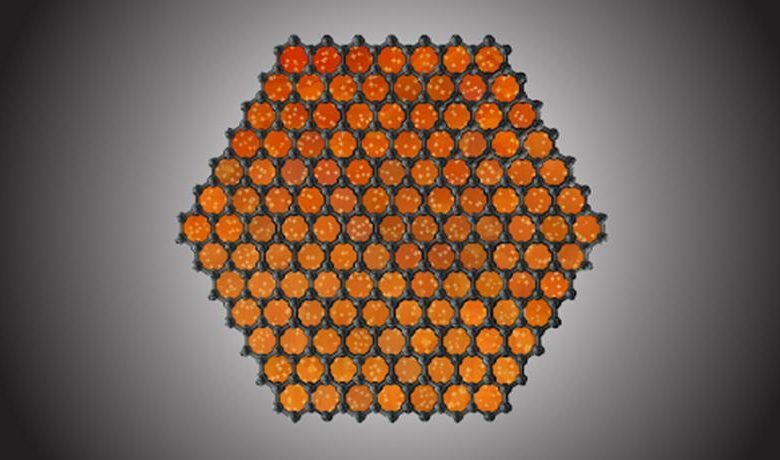

The process breaks the methane apart so that the carbon atoms can rearrange and realign themselves in a single honeycomb-shaped graphene layer. The advantage of this method over the ‘scotch-tape’ method is that CVD growth can create much larger graphene samples, centimeters or even meters in size. The output that comes from the ‘scotch-tape’ method, on the other hand, produces very small graphene, a few tens of micrometers in size.

Graphene’s CVD growth outputs are more widely usable than the outputs of the ‘scotch-tape’ method. However, the CVD-synthesized samples suffer from reproducibility problems and variable quality.

To tackle these challenges, the researchers have come up with an oxygen-free chemical vapor deposition (OF-CVD) method that can create high-quality graphene samples at scale.

While speaking about the innovation and its pioneering quality, James Hone, the senior author of the research and the Wang Fong-Jen Professor of Mechanical Engineering at Columbia Engineering, had the following to say:

“We show that eliminating virtually all oxygen from the growth process is the key to achieving reproducible, high-quality CVD graphene synthesis. This is a milestone towards large-scale production of graphene.”

The research, apart from what it achieved in the field of science and technology, also showed how academic collaborations must work. It was six years ago when Richard Martel and Pierre Levesque, co-authors of the research from Montreal, had shown that trace amounts of oxygen can slow the growth process and etch the graphene away. During that time, based on the findings of Martel and Levesque, Christopher DiMarco, GSAS 19, designed and built a CVD growth system where it was possible to control the amount of oxygen during the automation process.

The current study is a continuation of Martel, Levesque, and Di Marco’s work, where Xingzhou Yan and Jacob Amontree, current PhD students, found out that the CVD growth was much faster when the trace Oxygen was eliminated. The quality of these Oxygen-Free CVD-grown samples is virtually identical to that of exfoliated graphene, which is quite clean and free from impurities that could have otherwise interfered with the graphene’s desirable properties.

Apart from producing clean and pure graphene, the researchers found out that it was possible to predict CVD growth rate over a range of different parameters, including gas pressure and temperature.

In the days to come, the researchers plan to move forward with Graphene by developing a method for cleanly transferring the high-quality graphene from the metal growth catalyst to other functional substrates, such as silicon. This would greatly expand the possibilities of Graphene even further.

‘Clean’ Graphene: The Key to Commercialization

Graphene, from its early days, has earned traction for its many qualities. Its carbons are perfectly distributed in a hexagonal honeycomb formation, only 0.3 nanometres thick, with a mere 0.1 nanometres between each atom. This structural simplicity and purity endow Graphene with several properties.

For example, it is 200 times stronger than steel yet six times lighter. Its transparency is almost perfect, allowing about 98% of the light to pass through while absorbing only 2%. Graphene is also impermeable to gasses, and its properties could be altered by adding chemical components to its surface. Annick Loiseau from the National Office for Aerospace Studies and Research (ONERA) coined a slogan that said, “The future lies in pencil graphite!”

In essence, Graphene was ready to be commercialized. It was prepared for the big leap. Yet, one area that remained a contention was cleaning graphene while sustaining its size. The present research shows how to create clean graphene that is centimeters or even meters in size and make it ready for full-scale commercialization.

With the benefits of Graphene out there for everyone to explore and utilize, the scientific community became interested in looking into the possibilities of other monolayer elemental structures. The element that achieved distinction was Boron, with its monolayer being called the Borophene.

The Comparison Between Graphene and Borophene

Graphene and Borophene comprise single sheets of their respective elements. They have high structural strength, are highly flexible, and do not break down easily.

There are some differences as well. For instance, Graphene comes with planar sheets and a hexagonal lattice structure. Borophene sheets came with minor curvature and existed in three sub-allotropes with differing arrangements of triangles and hexagons.

We have already discussed the properties that Graphene possesses. Borophene’s properties make it a crucial element in photovoltaic, flexible electronics, and display technologies, owing to its high electrical conductivity and optical transparency along the ‘a’ direction and all kinds of novel anisotropy.

Overall, the development of Graphene and Borophene has made it possible to try out different technological innovations with interesting applied qualities.

In today’s discussion, which centers around Graphene, we will look into companies that were innovative in their application of Graphene. But before we examine individual companies and their achievements, we must examine the Graphene Flagship, the pioneering consortium that is opening up new horizons for working out different solutions with Graphene.

The Graphene Flagship

Funded by the European Union, the Graphene Flagship brings together 118 academic and industrial partners in 12 research and innovation projects and one coordination and support project ‘to advance Europe’s strategic autonomy in technologies that rely on graphene and other 2D materials.’

Over the past ten years, the Graphene Flagship has achieved many milestones. The latest and perhaps the most vital of these milestones so far has been the success of Graphene’s pioneering 2D material semiconductor integration project.

The project began in October 2020 to bring graphene and related materials (GRM) out of the laboratory and into scalable commercial production and usage. With a budget of 20 million Euros spread over four years, the 2D Experimental Pilot Line (2D-EPL) project focused on prototyping, wafer fabrication, and process enablement.

The results were promising, to say the least. Owing to the project’s achievements, academics, researchers, and private companies had a first-of-its-kind opportunity to test and prototype novel ideas for 2D material devices. This led to multi-project wafer (MPW) runs, which enabled low-cost, large-scale prototype development.

In the area of process enablement, the Graphene Flagship assisted the scientific community by constructing two bespoke new tools, including a metalorganic chemical vapor deposition (MOCVD) reactor from Aixtron and an automated 2D layer transfer tool by SUSS MicroTec. These tools made it possible to conduct thorough testing and modify 2D material growth and layer transfer processes, which are essential for achieving high production capabilities in the future.

While explaining the achievements of Graphene Flagship and its 2D-EPL project, Patrik Johansson, the director of the Graphene Flagship, had the following to say:

“The Pilot Line is not just about the hard data and scientific and technological advances that we have gathered together, but also — and perhaps even more importantly — the personal interactions that have created a playground for cross-fertilization of ideas for the future of 2D materials innovation in Europe. As the global graphene market is set to grow exponentially in size, from an annual revenue of 380 million US$ in 2022 to 1.5 billion US$ in just five years, projects like the 2D-EPL are vital in keeping Europe at the forefront of development and innovation.”

Apart from the Consortium, some individual companies and businesses have been doing stellar work in this field. In the segments below, briefly, we discuss a couple of such companies.

#1. NanoXplore

Founded in 2011 and headquartered in Montréal, Quebec, NanoXplore has a 4,000-metric-ton-per-year graphene powder production facility designed with a modular structure. The company specializes in developing and formulating graphene-based solutions as an additive to improve the performance of industrial materials within thermoplastics and thermosets.

The NanoXplore facility has best-in-class extrusion capabilities for creating graphene-enhanced masterbatches in polyolefins and engineered polymers. Through its patented proprietary clean technology, NanoXplore empowers its customers with a range of graphene-based solutions, including GrapheneBlackTM powder and graphene-enhanced masterbatch pellets. The Composites business division of NanoXplore offers standard and custom plastic and composite products to various customers in transportation, packaging, electronics, and other industrial sectors.

Graphene Black by NanoXplore is a multi-use graphene powder with the best balance of mixability and manufacturability. This allows graphene to increase its commercial viability and significantly improve the properties of plastics and polymers.

NanoXplore is also attempting to add GrapheneBlack to current Li-ion chemistries in silicon-enabled Li-ion anodes to improve energy capacity and charging speeds in its graphene-enhanced batteries that prove useful to electric vehicles, energy storage systems, and electric trucks and buses.

According to its latest financial reports, NanoXplore earned revenues of 33.87 million and nearly 92 million Canadian Dollars for the three-month and nine-month periods ended March 31st, 2024, respectively.

Another Company that has done well in clean manufacturing of Graphene Powder is GMG or Graphene Manufacturing Group Limited.

#2. Graphene Manufacturing Group Limited

It is a clean-technology company with a proprietary production process that manufactures Graphene powder from readily available low-cost feedstock. The process produces ‘high quality, low cost, scalable, tuneable, and contaminant-free graphene’ that helps develop solutions in the areas of energy saving and energy storage.

More specifically, GMG’s product line includes graphene-enhanced heating, ventilation, air conditioning, refrigeration (HVAC-R) coatings, lubricants, and fluids. The company is also working on the commercialization of GMG graphene aluminum-ion batteries that have the potential to have better energy density than lithium-ion batteries.

For the three-month and nine-month periods ending March 31, 2024, GMG earned revenues of 53,000 and 212,000 Australian dollars, respectively.

The Wonder Material of the Future?

Graphene’s breakthrough properties and features will enable it to achieve more in the future. It will be used in Electronics, Photonics, Energy, Biomedical, Composites, and designing the 2D materials of tomorrow.

These 2D materials offer exceptional physical and chemical properties, empowering ground-breaking applications in optoelectronics, energy, sensing, composites, and more. The key to growing fast would be developing ways that work with Graphene in the most sustainable and low-cost way possible.

Click here to learn how advanced single-atom layer materials like graphene and goldene open new doors for future discoveries.