Leveraging Rotaxane Structures for Next-Gen Release Systems In Medicine and Tech

Drug Delivery And Self-Repairing Materials with Rotaxane

Delivering molecules at a precise point is a very difficult task, but it is required for many medicines, like cancer treatments, to work. Until now, most delivery systems have been limited to activation by chemical interactions or suffered from poor performance. Similarly, self-repairing materials would need to release the repair system when exposed to mechanical stress. Thanks to a new molecular structure called rotaxane, discovered by researchers at the University of Manchester, UK, both of these innovations might be possible.

İçindekiler

What Is A Rotaxane?

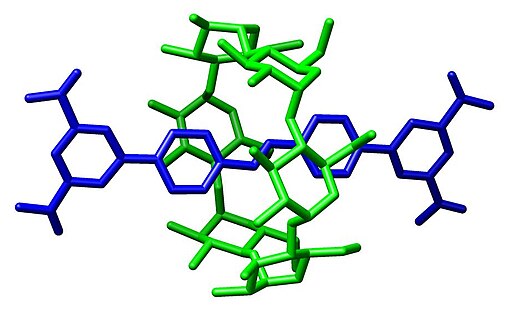

Rotaxanes are interlocked molecules, with a circular molecule (donut shape) having a longer polymer passing through its center.

Source: M stone at the English-language Wikipedia, CC BY-SA

In the case of the University of Manchester discovery, they used a long and complex molecule that is sensitive to mechanical force.

Along the chain of the molecule, they tied so-called “cargo molecules” of interest, in blue in this schematic:

Source: Nature

When force is applied to the material, the donut-shaped part of the rotaxanes pushes and releases the cargo molecules.

This makes this rotaxane molecule model a perfect detector of force and release mechanisms simultaneously.

Source: Nature

Improved Rotaxanes

A force-induced chemical release is not a new concept in itself. However, previous systems were limited in the number of molecules they could release, with only one molecule per force detector.

“Forces are ubiquitous in nature and play pivotal roles in various processes. Our aim was to exploit these forces for transformative applications, particularly in material durability and drug delivery.

“Although this is only a proof-of-concept design, we believe that our rotaxane-based approach holds immense potential with far reaching applications – we’re on the brink of some truly remarkable advancements in healthcare and technology.” – Guillaume De Bo, Professor of Organic Chemistry at The University of Manchester

Alternatively, physical encapsulation strategies can be used to deliver a larger cargo load, but these are often subject to non-mechanical unwanted release.

The new rotaxane design can instead release many molecules at once (up to 5) in a controlled fashion.

In practice, release can be triggered by either mechanical stress (for example, a shock or scratch on a phone screen) or targeted ultrasound, allowing for the targeted release of a drug only at a tumor site.

Another limitation of the previous system was the limitation on what types of molecules could be released, making them unfit for innovative drugs.

The researchers have demonstrated in their scientific publication in Nature that their system could be used for drug compounds, fluorescent markers, catalysts, and monomers, opening many potential applications.

In addition, such a system offers the possibility to release different cargo units in a defined sequence.

Rotaxanes Applications

Biotech

The most immediate application will be in drug delivery systems. Currently, this field is dominated by the growing usage of antibody-drug conjugates.

Thanks to the pinpoint nature of ultrasound therapy, rotaxane-based delivery systems could allow for drug delivery only at specific points of the body. The system has already been tested for delivery of doxorubicin, a potent wide-spectrum chemotherapeutic agent.

The initial research results demonstrated a 71% release efficiency using ultrasonication and 65% in the doxorubicin test.

Self-repairing Materials

Many materials, from metals to plastics, would benefit from being able to “self-heal” when suffering from mechanical stress, cracks, or impacts.

Because rotaxanes reacting to mechanical force would react only on the point of stress, they could be used to release repair systems right on the spot needed, before the damage gets more important.

This could open the possibility of self-repairing screens, metal parts, or even concrete.

The self-repairing properties would not last forever, but could significantly improve the durability of materials. Especially as it would need the damages to be occurring in the same spot twice, where the rotaxanes are already depleted, for the repairing properties to fail.

Sensors & Safety

As this new rotaxane system can also be used to release fluorescent markers (and potentially color markers), it could be used as a “warning system” for damage that would otherwise stay invisible. This could be very useful to reveal mechanical stress or metal fatigue in structures and machines before an actual catastrophic break occurs.

It could equally be used to prove the integrity of a seal or container, like on pharmaceutical or food products.

Rotaxane Companies

Rotaxanes are, for now, very much an experimental class of molecules that are mostly produced and studied in labs. However, some companies are experimenting with self-repairing material and ultrasound-based drug delivery.

1. EXACT Therapeutics (EXTX)

This biotech startup is leveraging its acoustic-mediated therapies (Acoustic Cluster Therapy or ACT) to treat cancer by increasing the uptake of chemotherapy by the cancer cells.

Source: Exact Therapeutics

The company is currently in phase 2 of clinical trials for pancreatic cancer and phase 1 for patients with liver metastases secondary to colorectal cancer.

It currently uses negatively charged microbubbles and positively charged microdroplets, but it could also use rotaxanes in the future for even more concentrated and efficient drug delivery.

2. Arkema (AKE.PA)

The French company is a chemical product manufacturer, created as a spin-off from petrochemical company Total, focusing on adhesives, coatings, and advanced materials, each roughly 1/3 of the total activity.

Notably, it has been working on self-repairing elastomers and rubbers since 2009.

The company is active in many chemical classes and is used in virtually all industries.

Source: Arkema

Arkema’s strategy is to be the leading supplier in each niche it occupies, being the world’s # 1 to #3 in 90% of the portfolio.

Considering the long-established presence in self-repairing material and the valuable IP of the company, it could make it a prime candidate to deploy commercial rotaxane technology in the future.

3. Autonomic Materials

Source: Autonomic Materials

The privately-listed company specializes in self-healing materials, especially coatings against corrosion, with a wide range of applications and industries.

The company’s coating chemicals react as soon as a micro-crack appears, preventing further damage from spreading. If the damage is too large, it also reseals the edges of the damage zone, preventing loss of adhesion and subsequent delamination of the coating.

The company claims a very high performance while also achieving a very low level of VOC (Volatile Organic Compounds) emissions, something that can be toxic and cause safety issues in industrial settings.

Source: Autonomic Materials