‘Sticky Metal’ Could Have Widespread Applications in Robotics, Energy Storage and Even BioTech Solutions

Sticky Metal For Soft Robotic

One issue that development in robotics keeps stumbling upon is the development of robots and systems that can deal with the real world. This often requires flexibility and “soft” parts, instead of purely mechanical constructs.

İçindekiler

Different approaches are being experimented with. Notably, we previously reported on one: creating new magnetic material to create so-called “soft robotics,” which we discussed in detail in our article “Magnetic Gel Capsules Could Advance Both Robotics and Medicine.”

However, another approach would be to tie together metallic and soft parts. This has historically been difficult, with metal-organic junctions the main issue.

This problem might have been solved by researchers Wenhao Xu, Faraz A. Burni, and Srinivasa R. Raghavan, working at the University of Maryland, USA. They developed a type of “sticky metal” able to create a strong and durable junction with most soft materials like hydrogel, muscles, and plants.

How Sticky Metal Works

The discovery relies on a new principle the researchers called hard–soft electroadhesion (EA).

They are still looking to fully explain how it works, but here is what they already know.

Only Some Metals Display EA Properties

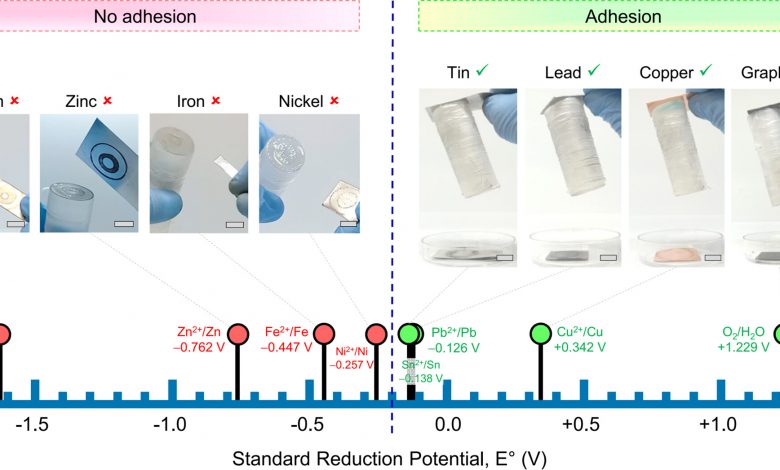

Not all metals can be used for EA. Metals that do have positive reduction potential, while those that do not have negative reduction potential.

Metals that do not adhere are those that get oxidized first at the anode. This oxidation (electrolysis) of the metal dominates over any competing processes, which explains why there is no adhesion.

Conversely, metals that do adhere are relatively inert, allowing the polymer chains of the gel network to become oxidized first at the anode.

Source: American Chemical Society (ACS) Central Science

This excludes common metals like titanium, zinc, iron, and nickel, and that may explain why EA was not discovered until now. However, this still includes common and cheap metals like tin, lead, copper, as well as graphite (which is not a metal, but pure carbon). So, while this might be a limitation, this should not be a deal breaker for any use in robotic applications.

How Does It Work?

EA is created when a current is applied to the metal.

The theory is that the oxidation of the soft material (gel or other) creates chemical bonds between the metal and the polymer chains. These chemical bonds create a strong junction between the metal and the soft material, leading to strong adhesion.

The process can also be reversed easily by applying an inverse current. This creates reductive chemical conditions, which “dissolve” the chemical bond and cancel the adhesion.

Source: American Chemical Society (ACS) Central Science

This theory is reinforced by experiments that demonstrated that any change occurring on the hydrogel occurs only at the surface of contact with the metal.

It also seems that the exact nature and characteristics of the chemical bond will vary depending on the respective chemistries of the metal and the soft material.

Source: American Chemical Society (ACS) Central Science

What Can Sticky Metal Glue to?

The published scientific paper mostly focuses on adhesion to various types of hydrogels, as they made for a good material to modify and experiment with.

However, the principles can be applied to plenty of other materials, including animal muscles or even tomatoes. Overall, the only requirement for the soft material is for it to be an ionic conductor, which is the case for almost all biological tissues.

Source: American Chemical Society (ACS) Central Science

Equally impressively, EA can also occur underwater, where adhesion can be a very difficult thing to achieve.

Possible Applications Of Sticky Metals

Robotics Gripping

The first and likely most immediate application of EA is developing better grippers for robots. Properly grasping things without dropping or squishing them to a pulp has been a persistent issue for robots.

EA does not require a robot finger to have fingers, hands, joints, or other complex & specific shapes. So this could open the way for cheaper, more efficient, and safer alternatives to the currently used methods.

Source: Corteva

Batteries

Efficient and easy-to-manufacture batteries are in high demand from EVs and the growth of renewables in the energy mix. Most batteries rely on connecting two hard metallic (or graphite) solid anode and cathode with an electrolyte between them.

Very often, the electrolyte is a gel in an ion-conductive solvent.

So, the University of Maryland’s researchers tested whether they could use EA to create a new type of battery.

They used copper and zinc for electrodes and managed to create a 0.9V battery.

Source: American Chemical Society (ACS) Central Science

This was just a proof-of-concept done by non-battery specialists. However, they think that flexible and rechargeable batteries could be created using the same principles. And it could open the way for a new battery manufacturing method.

Soft Robotics

As previously mentioned, robotic engineers have long dreamed of robots mixing hard and soft components, imitating how animals have both hard bones and soft muscles & tissues.

A rudimentary test was done to illustrate how EA can be used for this purpose. For this, a mix of hard components (graphite plates) and soft components (hydrogel) was used to create a “load-bearing hard–soft structure”.

Source: American Chemical Society (ACS) Central Science

Using increasing loads, the structure first supported it and then started to bend. When this weight was removed, the gel pillars retracted to their original state, and so the top slab moved upward.

Hard elements alone will not be compressible or deformable, whereas soft elements alone could be crushed by a load. The combination, however, can bear a load flexibly without damage.

By being able to compress and “push back”, such a system could be used for making actuators and robots able to interact with their environment in a delicate manner.

Underwater Adhesive

Gluing anything in a water-rich environment or underwater can be a technical challenge. The adhesive bonds are often influenced by the water molecules around them and are weaker than required in most cases.

Here, adhesion is an electrochemical phenomenon that is only switched on when the gel and metal are contacted under a current. Because EA relies on actual chemical liaison, it is not affected by the surrounding water.

Prosthetics And Implants

Another potential use of sticky metal is in biomedical applications. The compatibility of metal with the human body has always been an issue in using metallic implants. Connecting the metal to the soft tissues without damaging them is a difficult process.

If implants or prosthetics like limb replacements could be made to stick to soft tissues, they could become a lot more functional and practical to use. It could also improve significantly the quality of life of patients.

Image by RAEng_Publications from Pixabay

And because the process is easily reversible by inducing an electric current, sticky implants are likely to be a lot easier to replace or remove as well.

Advanced Application with Sticky Metal

Hard–soft ElectroAdhesion or EA is a remarkable discovery with many possible applications.

Not only does it work with virtually all ionic gels and organic tissues (almost anything containing water and salts), but it can also be used with cheap base metals like tin, copper, and even graphite. Thanks to these low-cost materials, any industrial application has a chance of being cost-competitive.

It could completely change the field of robotics, starting with better grippers, especially for food products like meat, fruits, and vegetables. Then, it would allow for the creation of true soft robots that mix hard and soft/elastic parts.

It could also allow for much easier links to the body prosthetics and implants, bringing us one step closer to true cybernetic technology.

Lastly, it could have applications beyond robotics and prosthetics, potentially creating new types of batteries as well as underwater & reversible adhesives.